|

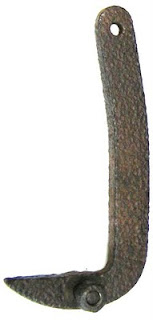

| Grubby looking thing! |

|

| Alternative view |

|

| With mounting flange and whistle-mounting elbow |

|

| Whistle valve roof-mounted in Isebrook |

|

| Whistle valve roof-mounted in William |

|

| Front-mounted whistle (the valve is inside) |

|

| Functional Parts |

|

| Conical valve (not to scale!) |

|

| Valve seat inside end of valve body |

|

| Spring and retainer which screws into the end of the valve body |

|

| Rod (not much more to say on this!) |

|

| Operating lever |

The steam pressure holds the conical valve in place until the lever is used to push it open. This is a sudden action which is also terminated abruptly by the steam forcing the conical valve shut again. Hence the whistle valve enables a quick 'pop' to be achieved as well as the long 'poop'!

There is one more aperture in the valve body shown with a copper tube attached in the Isebrook valve picture (but, oddly, not on William).

|

| Condensate drain |

When it's all assembled, it looks like this.

|

| Note the elegant MDF cab front substitute and supporting clothes' peg! |

No comments:

Post a Comment